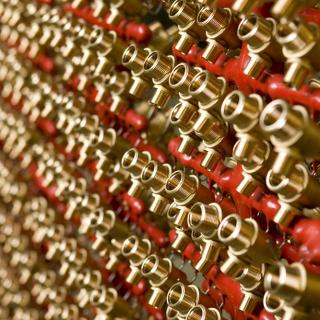

At AlfaTech we remove lead from brass components using the patented RUVECO® process.

It is a selective, effective and economical eco-friendly process that removes lead from brass, and can also be applied to parts that are already chrome plated, without altering the technical-aesthetic characteristics, making the parts compliant with the most restrictive European and international standards on lead contamination – including ANSI/CAN 61 (USA and Canada), AS/NZS 4020:2018 (Australia, New Zealand), EN 16889:2016 and Directive 98/83/EC (European Union) –, and the recent EU guidelines on safe drinking water (Council Conclusions on EU Human Rights Guidelines on Safe Drinking Water and Sanitation, 17 June 2019).

Lead is essential for the machinability of brass, but harmful to human health already at concentrations above 10 µg/l.

Lead removal is an environmentally friendly chemical treatment that is selective with respect to lead and acts in the first 20 µm of the brass surface. Effective even on undercuts or complex geometries, it can be carried out either on a frame or a rotary barrel.

Lead removal is an effective and very cost-effective solution that avoids the need to use more expensive lead-free or low-lead alternatives to the materials normally used, modifying the production process or supply chain.

In this section you can download the PDF for the specific process.

Ruveco® is a chemical process (no current is used) to remove lead from the surface of brass and bronze, thanks to its selective nature. It can also be referred to as “unleading”.

Brass, although low in lead, contaminates drinking water and foodstuffs (coffee, soft drinks,....) that come into contact with it. Lead is a contaminant that accumulates in the body and is toxic (especially to children), which is why the regulations in many countries have aligned with the WHO (World Health Organisation) guidelines.

After machining and any galvanic treatment (nickel chrome) and before assembly.

This chemical (non-electrolytic) process does not change the final appearance, leaving the initial colour unchanged.

The Ruveco®Plus process does not affect or dull chrome surfaces.

The Ruveco® process selectively removes lead from the first 20µm of the surface it comes into contact with. Hot pressurised water or steam can “burrow” into the surface of brass, bringing untreated surfaces into contact with water. In these cases, we recommend the TEA+® treatment.