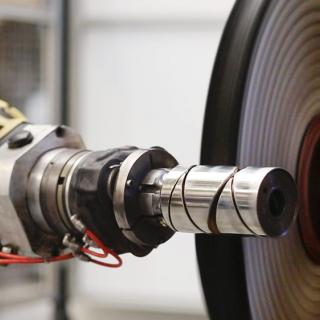

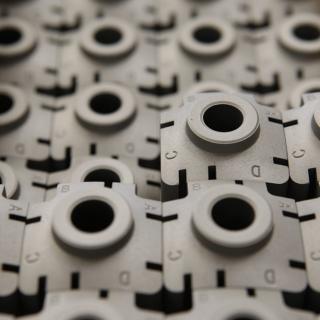

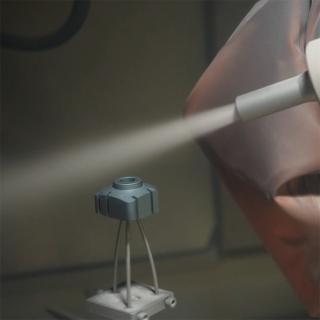

Depending on the material to be coated and your requirements, before and after the surface treatments of RUVECO® lead plating, TEA+® Ternary Eco Alloy, RONALLOY™ GT 300 / T.E.A.® B coating, hard chrome plating and chemical nickel plating, we also carry out preparation and finishing treatments of metal components.

In this section you can download the PDF for the specific process.