The surface treatment TEA PLUS® Ternary Eco Alloy deposits an environmentally friendly intermetallic alloy of tin (67%) and nickel (33%) with an Sn–Ni ratio of 1:1. It yields semi-glossy, extremely passive deposits, free of micro-cracks and with excellent guarantees of resistance to wear.

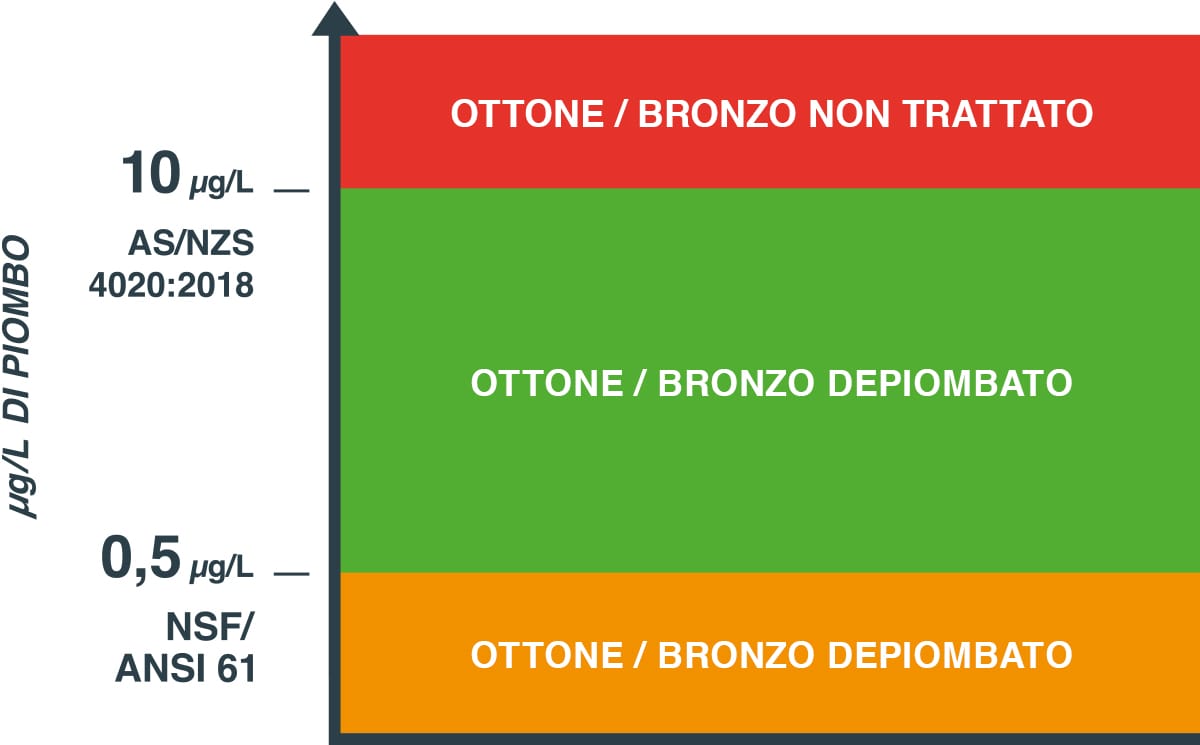

It complies with international drinking water limits:

Resistance to corrosion

The TEA+® coating is generally applied after the RUVECO® lead stripping process to prevent the progressive deterioration of brass, which in components subjected to extreme working conditions, such as steam passage above 100°C or frequent descaling cycles, feeds the circulation of lead in water or in the liquids that it comes into contact with.

December 2020: TEA PLUS® has been approved by the German Federal Environmental Agency (Umweltbundesamt - UBA) and included in the “4MSI Composition List”.

This list defines the metallic materials approved in the member states of the 4MSI group (Germany, UK, Netherlands, France and Denmark) as suitable for use in contact with drinking water.

In the downloads section at the bottom of the page you can find the updated “Positive List”, where on page 40 our Sn/Ni coating is included among the “platings”.

To view the “Positive List”, please see the downloads area below.

| TEA PLUS® | Ni–Cr | Base material / brass |

|

|---|---|---|---|

| Nickel release in H2O: LOW | LOW | HIGH | LOW |

| Lead release in H2O | LOW | HIGH | HIGH |

| Hardness | HIGH | VERY HIGH | LOW |

| Resistance to corrosion | GOOD | GOOD | LOW |

| Internal deposit | GOOD | LOW | N/A |

| Homogeneity | GOOD | LOW | N/A |

Nickel release in H2O: LOW

Lead release in H2O: LOW

Hardness: HIGH

Resistance to corrosion: GOOD

Internal deposit interno: GOOD

Homogeneity: GOOD

Nickel release in H2O: HIGH

Lead release in H2O: HIGH

Hardness: VERY HIGH

Resistance to corrosion: GOOD

Internal deposit: LOW

Homogeneity: LOW

Nickel release in H2O: LOW

Lead release in H2O: ALTO

Hardness: BASSA

Resistance to corrosion: LOW

Internal deposit: N/A

Homogeneity: N/A

In this section you can download the PDF for the specific process.

It is applied directly on copper, copper and nickel alloys, white bronze (RONALLOY™ GT 300 / T.E.A.® B) and silver.

Thicknesses of 2-4 microns, thanks to the extreme passivity of the coating, which is free of micro-cracks, guarantee a long service life and resistance to descaling or acid cleaning cycles, as well as hot water and steam.

One of the guarantees given by this carry-over is the very high repeatability and consistency of the colour over time, as well as the uniformity of the colour between batches.

After machining and before assembly.

TEA+® is an intermetallic Sn (67%) – Ni (33%) alloy; Sn–Ni ratio 1:1;

RONALLOY™ GT 300 / TEA® B is a deposit of Copper (62%) and Tin (38%) --> Cu3Sn