Zinc phosphating is a chemical surface treatment that transforms the surface of steels and cast irons into a microcrystalline coating composed of zinc phosphates. This process is used to improve the adhesion of subsequent coatings (such as paints or rubbers), to increase corrosion resistance and to reduce wear in mechanical applications.

Due to the porous nature of the phosphate layer, the treatment favours the retention of protective oils and lubricants, improving the tribological behaviour of components. Zinc phosphating is used in a variety of sectors, including automotive, industrial mechanics and the energy sector, on small or large parts, whether machined by frame or barrel.

It is particularly suitable as a preparation for painting or gumming, or as a temporary or definitive anti-corrosion treatment, even in moderately aggressive environments.

| Reference standards | UNI EN ISO 9717:2017; ASTM F1137; DIN 50942; MIL DTL 16232; AMS03 11 |

| Layer structure | Microcrystalline, porous, with needle-shaped or prismatic crystals |

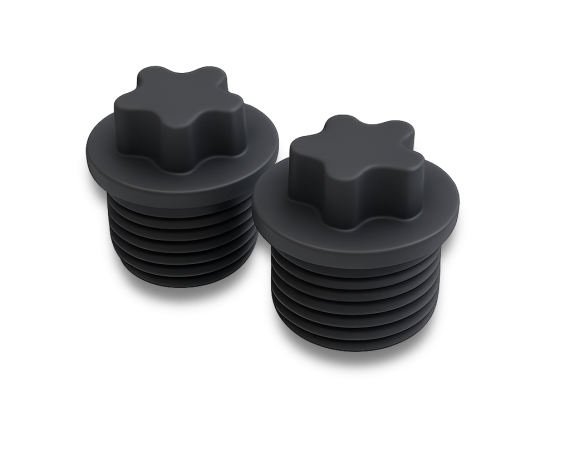

| Colouring | Light to dark grey, influenced by substrate composition |

| Corrosion resistance | 24-48 hours in salt spray according to UNI ISO 9227, if oiled |

| Final treatments available | Oiling (for corrosion protection) or drying with passivation |

| Appliability | Suitable for iron, carbon steel, alloy steel and cast iron components |

| Processing methods | Frame (static) or rotary barrel (dynamic), depending on the geometry and dimensions of the parts |

| Compatibility with other processes | Excellent base for painting, gumming, Teflon coating and applying lubricants |

Reference standards: UNI EN ISO 9717:2017; ASTM F1137; DIN 50942; MIL DTL 16232; AMS03 11

Layer structure: Microcrystalline, porous, with needle-shaped or prismatic crystals

Colouring: Light to dark grey, influenced by substrate composition

Corrosion resistance: 24-48 hours in salt spray according to UNI ISO 9227, if oiled

Final treatments available: Oiling (for corrosion protection) or drying with passivation

Appliability: Suitable for iron, carbon steel, alloy steel and cast iron components

Processing methods: Frame (static) or rotary barrel (dynamic), depending on the geometry and dimensions of the parts

Compatibility with other processes: Excellent base for painting, gumming, Teflon coating and applying lubricants

In this section you can download the PDF for the specific process.

Zinc phosphating is ideal for corrosion protection and as a base for paints, while manganese phosphating is suitable for anti-seize and anti-wear applications.

Yes, the phosphated layer improves corrosion resistance, especially when combined with a final treatment such as oiling or painting.

Absolutely. Phosphating is often used precisely as a pre-treatment to improve the adhesion of the paint to the metal surface.

Mainly steels and cast irons. It is not suitable for aluminium, copper or non-ferrous alloys.

Yes, the treatment can be carried out either by rotobarrel (for small and large parts) or by frame (for larger or delicate parts).

No specific maintenance is required on the phosphate coating, but the protection over time also depends on the operating environment and any subsequent coatings applied.